¡Advertencia! El contenido en esta página está disponible solo en los siguientes idiomas: Inglés

Customer

Nestlé | Konolfingen, Switzerland

Customer Challenge

Manufacture trial batches of baby milk under aseptic condition within an isolator, with complete process and equipment integration: sterile transfer from fermentation, centrifugation, separation, mixing and can filling.

Performance Requirements – Nestlé

- Sterile transfer from fermenter, positioned outside isolator, to inside isolator

- Centrifuge for 1 liter bottles

- Separation with peristaltic pump and mixing with magnetic stirrer

- Can filling with peristaltic pump and can closing system

- Sterile environment inside the isolator

Solution Highlights – Nestlé

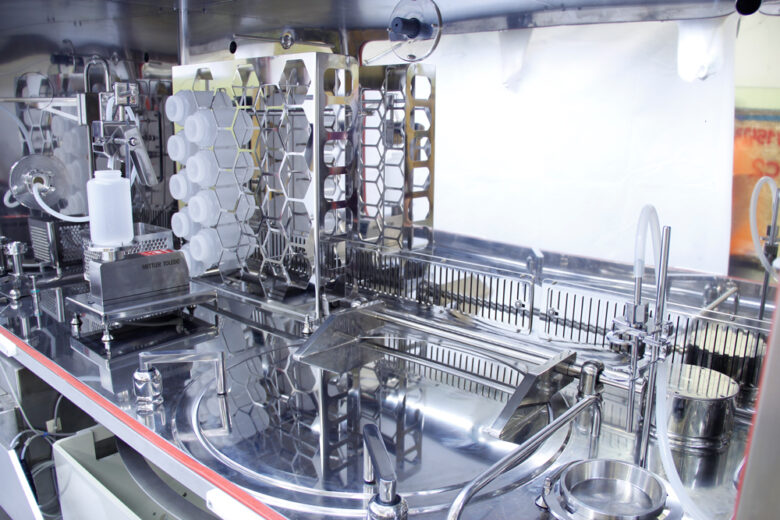

Comecer Process Engineering studied, designed and manufactured an isolator with complete process integration, including a special centrifuge, and can filling/closing system.

- Complete custom aseptic multi-chamber isolator (5 meters long, with 2 chambers and transfer chamber): centrifugation, separation, can filling/closing and outlet chamber

- Complete custom fitting with internal solutions for tools and ancillaries arrangement

- Laminar air flow in all chambers

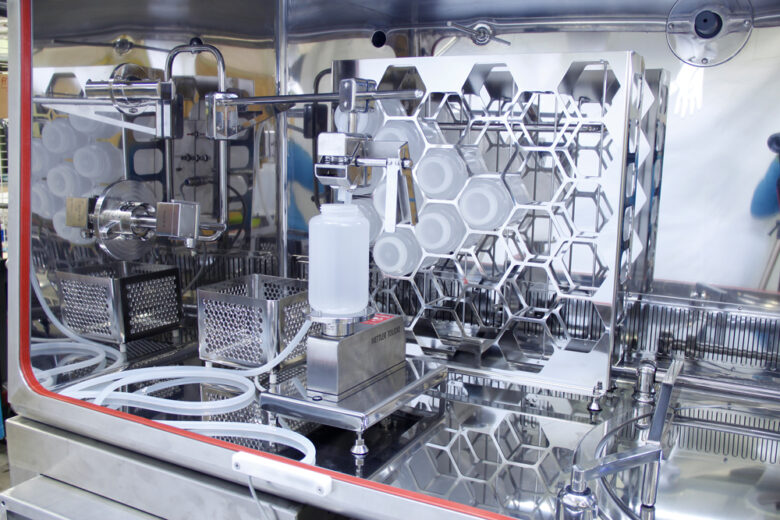

- Special centrifuge for 1 liter bottles with unique isolator integration

- Separation system and can filling with integrated special peristaltic pump

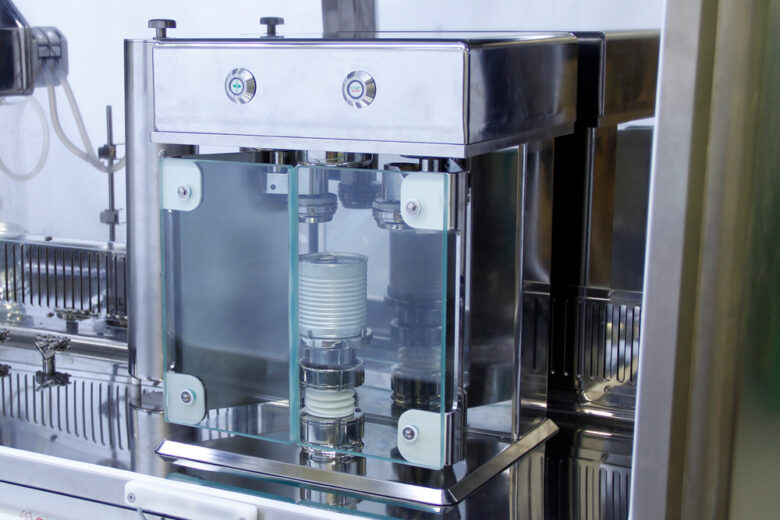

- Can closing system with complete integration

- Integrated bio-decontamination systems using the purest hydrogen peroxide solution to achieve a 6log decrease in contamination

Applying isolation technology to such different processes requires deep innovation. Our approach, supported by full customization capabilities, can give precise directions on the technological solutions as well as the procedures to be implemented.

Ubicación: Konolfingen

Categoría: Pharma