- Products

- Video

- Events

- News

- Landing

- Pages

for different starting points

that fit every application

for different products and output models

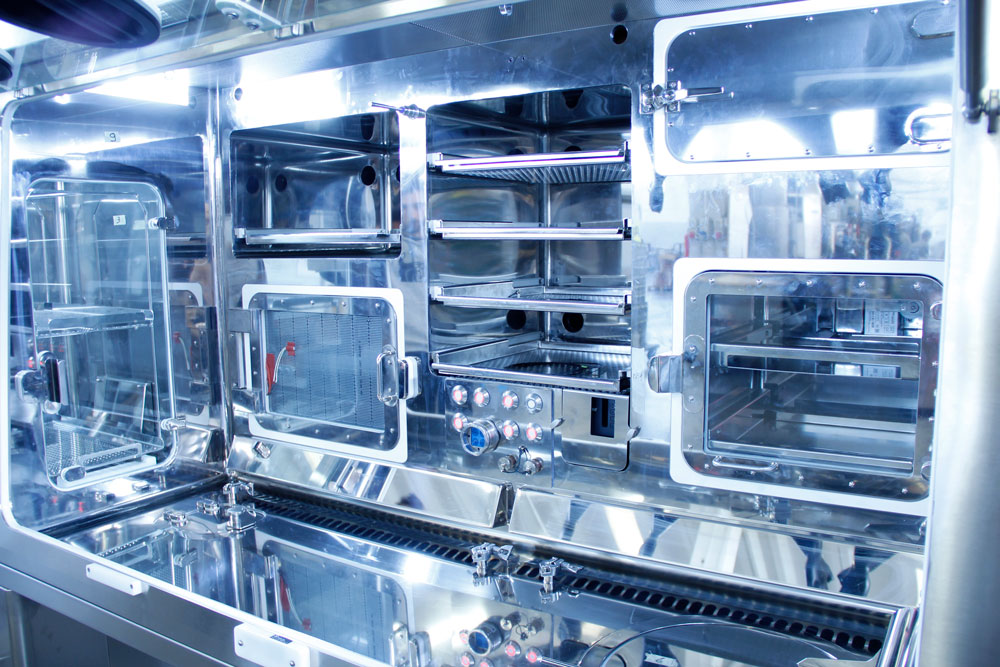

– Isolation Technology advantages: superior cleanliness and no operator contact

– Grade A processing chamber

– Inlet options from D to A for different materials

– Modular system: allows for customization

– Fully integrated working accessories

– Flexible, for different products and processes

– 21 CFR part 11 compliant

– Process automation available on request

– Grade A external Incubator

– Aseptic Connection via RTP with Main Processing Unit

– Automatic or semi-automatic transportation

– Wi-Fi and RFID monitoring

– Adapt the equipment; don’t change the process

– Tested with multiple culture containers

– Scale-up/out is just an add-on

– Monitored, alarmed, and remote-controlled

– Grade A or Grade C filling options

– Isolator integrated or independent filling options

– Modular, adaptable to different filling speeds and filling containers

– Customizable for different filling Single Use Sets (SUS) or different bulk origin

– Refrigerated on request

– Remote control possible if required

Comecer, an ATS company, designs and manufactures customized isolation technology equipment for pharmaceutical and biotech applications. Its asepsis offerings include isolators designed for sterility tests and formulation of sterile drugs, isolators or RABs integrated into filling lines, and dedicated solutions for Cell & Gene Therapy applications (ATMP), including the innovative FlexyCult incubation system for Advanced Therapy Labs.

Comecer’s vision is to contribute to the progress and preserve life by developing highly innovative technologies and sustainable solutions, pursuing the latest rules of GMP (Good Manufacturing Practices) in Cell & Gene Therapy. Read more about us.

Download this and other data sheets

Log In Lost PasswordNews and invitations to events and fairs directly in your mailbox

Subscribe